What Is a Pre Insulated Tube Bundle?

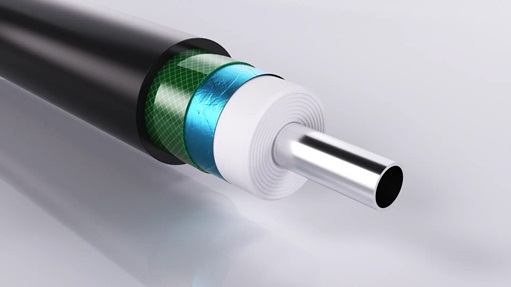

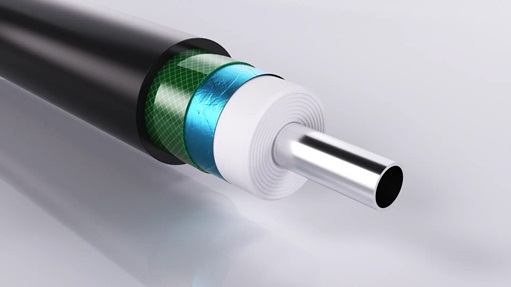

A pre insulated tube bundle is a specialized assembly of multiple small-diameter tubes encased within a protective insulation layer and an outer jacket. Its primary function is to maintain the temperature of fluids or gases as they travel between process instruments, analyzers, or control systems. By integrating thermal insulation and sometimes electrical tracing cables within the same sheath, a pre insulated tube bundle prevents heat loss, condensation, or freezing—making it an essential component in process control and measurement systems. In industries such as petrochemical, power generation, and chemical manufacturing, where precision and stability are critical, the use of pre insulated tube bundles ensures accurate readings and continuous performance even in harsh environments. The advanced engineering and thermal control technology developed by Jiahong make these systems ideal for long-distance installations where maintaining consistent process temperature is a necessity.

Why Is Pre Insulated Tube Bundle Important in Industrial Applications?

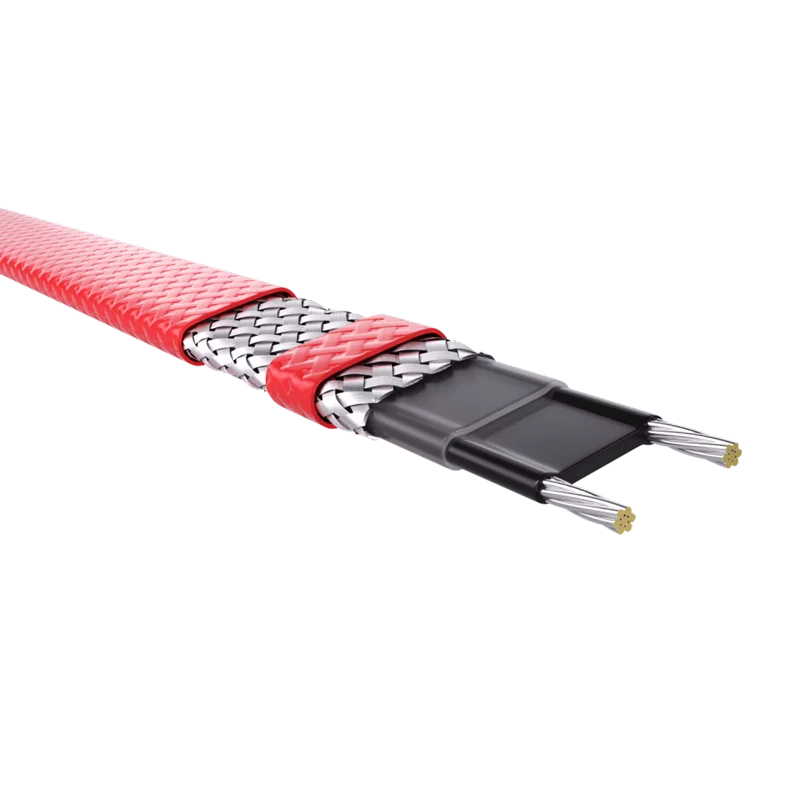

The importance of a pre insulated tube bundle lies in its ability to provide both thermal efficiency and protection. In process industries, temperature fluctuations can cause viscosity changes, inaccurate measurements, and even product quality issues. Pre insulated tube bundles effectively prevent these risks by creating a controlled thermal environment around the tubing. They are particularly valuable for transmitting temperature-sensitive liquids such as crude oil, chemicals, or analytical samples that require consistent conditions from the process point to the control panel. The insulation materials used in pre insulated tube bundles—such as polyurethane foam or mineral wool—minimize heat transfer and resist moisture ingress. This not only stabilizes process temperature but also extends the lifespan of the tubing by protecting it from corrosion and mechanical damage. In cold climates, integrating heating elements into the pre insulated tube bundle ensures continuous operation, preventing freezing or blockages that could disrupt industrial processes.

What Are the Key Features of a High-Quality Pre Insulated Tube Bundle?

A reliable pre insulated tube bundle combines durability, flexibility, and precise temperature control. The inner tubes, typically made from stainless steel, copper, or polymer, are selected according to the chemical compatibility of the medium being transported. The insulation layer plays a crucial role in maintaining the desired temperature, while the outer jacket protects the system from weather, UV radiation, and mechanical stress. Jiahong's pre insulated tube bundles are designed with multi-layer protection to ensure consistent performance even under extreme temperature variations. The bundles can also be customized to include self-regulating heating cables that adjust output automatically based on ambient conditions. This integration of electrical heat tracing within the tube bundle enhances safety, reduces energy waste, and maintains a stable operating temperature across long distances, making it an efficient solution for modern process industries.

Comparison Between Pre Insulated Tube Bundle and Conventional Tubing Systems

Feature | Pre Insulated Tube Bundle | Conventional Tubing System |

Temperature Control | Integrated insulation and heat tracing maintain stable temperature | External insulation often insufficient or uneven |

Installation | Factory pre-assembled, easy and clean installation | Requires on-site insulation and tracing work |

Durability | Resistant to weather, UV, and mechanical stress | More exposed to corrosion and damage |

Maintenance | Minimal due to integrated design | Frequent inspection and repair needed |

Energy Efficiency | High efficiency due to reduced heat loss | Lower efficiency from inconsistent insulation |

This comparison shows how a pre insulated tube bundle provides significant advantages in terms of temperature management, durability, and ease of installation. It eliminates many issues faced in traditional tubing systems, particularly when installed outdoors or across long distances.

How to Select the Right Pre Insulated Tube Bundle for Your System?

Choosing the right pre insulated tube bundle depends on several factors, including the type of fluid, required temperature range, installation environment, and distance between connection points. For example, chemical plants handling corrosive or volatile substances may require stainless-steel tubing with high-temperature insulation, while analytical applications might favor polymer-based tubes with precise heat tracing control. The selection of insulation material—whether polyurethane, polyethylene, or mineral fiber—should be based on the thermal performance needed and the operating conditions. Jiahong's engineering expertise allows for tailored solutions, ensuring that each pre insulated tube bundle meets the exact operational and safety requirements of the project. Proper installation and connection also ensure consistent heating and insulation integrity, reducing the risk of temperature drop or process interruption in critical applications.