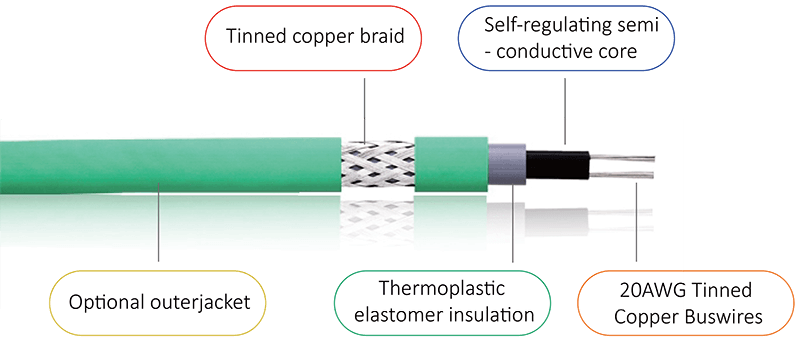

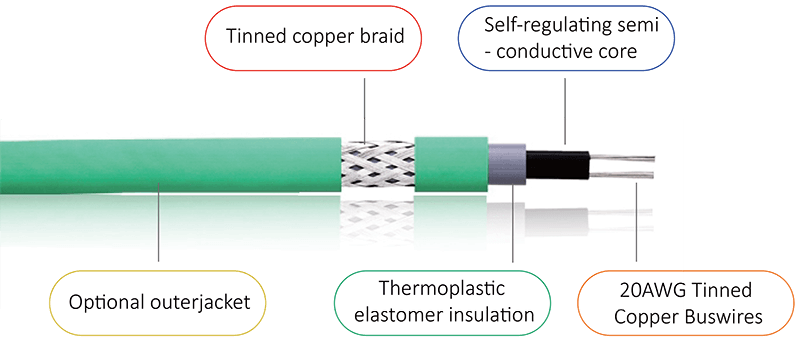

A Typical Jiahong Self Regulating Heating Cable consists of 5 different layers. The structure includes

- Inner alloy conductor

- PTC heating element

- Inner insulation or PTC Insulation

- Anti-electromagnetic radiation braid

- Outer water-proof jacket.

Graphic: The Basic Structure of Self-Regulating Heating Cables

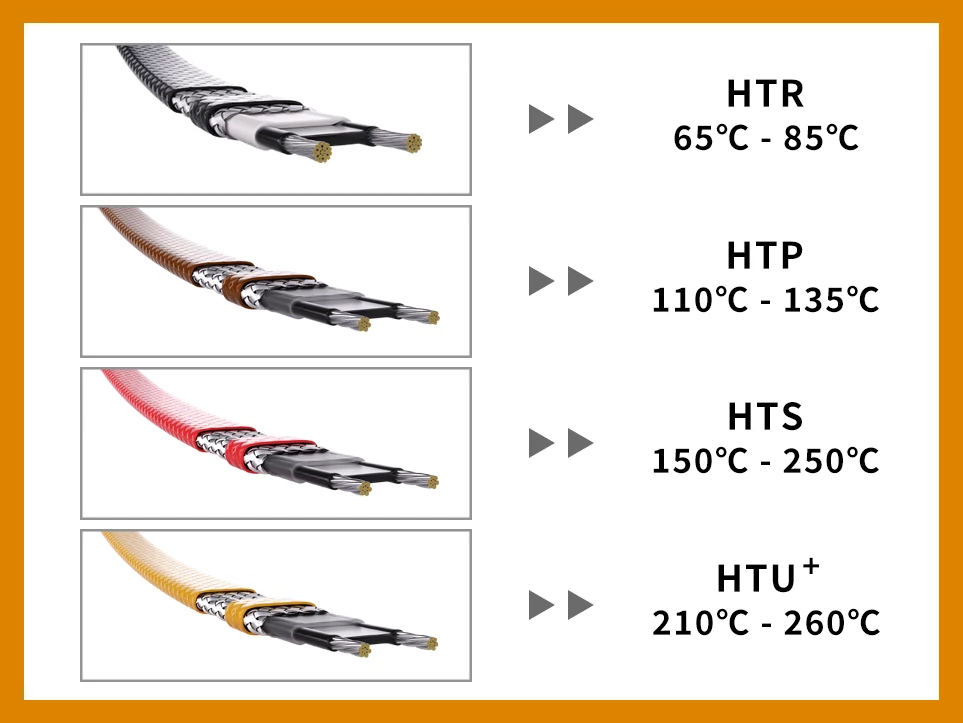

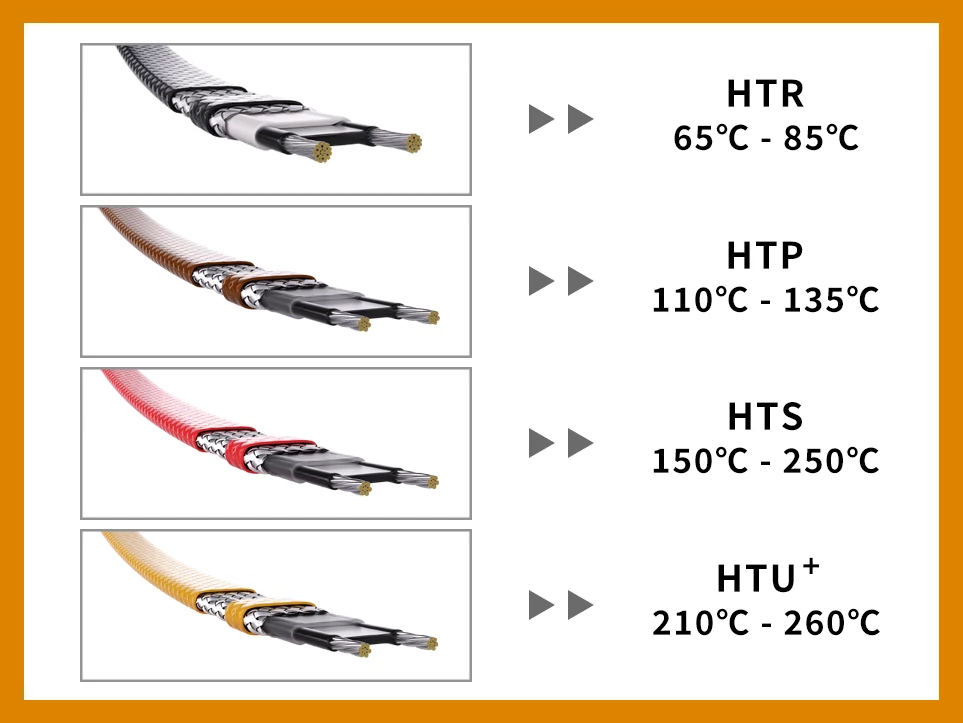

Jiahong Self Regulating Heating Trace includes three types:

- Low-temperature Self-Regulating Heating Cables

- Medium temperature Self-Regulating Heating Cables

- High-temperature Self-Regulating Heating Cables

- Ultra -High-temperature Self-Regulating Heating Cables

Graphic: Various of Self-Regulating Heating Cables Working Effect

Low-Temperature Self Regulating Heating Cable

It has a maximum maintenance temperature of 65 degrees Celsius and a maximum intermittent exposure temperature of 85 degrees Celsius.

This kind of heating cable is widely used in various applications such as residential, commercial, industrial areas, etc.

For example, heat tracing for small diameter metal, PVC pipes, roof, gutter de-icing and small size industrial pipe freezing protection. Our regular models are SLL, HTLe, HTM, and HTR.

Medium Temperature sr heat trace

It has a maximum maintenance temperature of 110 degrees Celsius and a maximum intermittent exposure temperature of 135 degrees Celsius.

This heat trace cables are suitable for large pipes and systems with high heat loss to prevent freezing while maintaining the temperature.

Our regular model is HTP.

High-Temperature Self Regulating Heating Cable

It has a maximum maintenance temperature of 120 degrees Celsius and a maximum intermittent exposure temperature of 200 degrees Celsius.

It is a kind of industrial-grade self-regulating heat trace cable.

It can be used in environments with a maximum temperature of 150oC. It is waterproof, anti-inorganic, anti-friction and anti-extrusion.

It is used in general and hazardous environments. Our regular model is HTS.

Ultra-High-Temperature Self Regulating Heating Cable

It has a maximum maintenance temperature of 205 degrees Celsius and a maximum exposure temperature of 260 degrees Celsius.

It is a kind of industrial-grade self-regulating heat trace cable.

It can be used in environments with a maximum temperature of 205oC. It is waterproof, anti-inorganic, anti-friction and anti-extrusion.

It is used in general and hazardous environments. Our regular model is HTU+.

Jiahong has the only CSA standard testing Lab in China.

The Lab can provide 4 categories, 26 total different tests which include conductor tests, plastic material tests, printing ink tests, and packing materials tests.

All heat trace wires must pass 7 categories and 79 tests for quality control. These tests include stranding, PTC extruding, insulation extruding, outer jacket extruding, irradiation, braiding, lapping, etc.

What’s more, Jiahong electrical heat tracing must go through 2 times, 100% inspections before finishing and final packaging.

There are a total of 15 tests, and key tests are resistance, insulation resistance, and high-voltage insulation tests.

All Jiahong Self Regulating Heating Cables are approved by most international testing institutions.

Graphic: Jiahong Testing Reports for Self Regulating Heating Cables

The heating cables for North America must UL, CULus, CSA, and ETL. For the European Market, self-regulating heating cables must pass the CE, TUV, ATEX, IECEX, and EAC. Moreover, our self-regulating heating cables have a 10-year warranty.

A self-limiting heating cable adjusts its power output along its entire length, making it a reliable solution for many applications including industrial, residential, and commercial areas as earlier mentioned. Also, the heating cables are very economical and long-lasting.

For example; you can use self-regulating heating cables in locations where home and commercial water supply and drain pipes can freeze, in industries to prevent certain fluids from freezing, or even for composite curing on large structures such as yachts, airplanes, and so much more!

No matter how well you insulate them, water tanks and drainage pipes will freeze if the surrounding temperature drops below 0 degrees C. Low temperatures can lead to cracked water tanks and canals which will eventually cost you a lot of money to repair.

So why install self-limiting heating cables? Simple; because these systems provide a reliable and long-term solution to operational disturbances and costly damages.

The only way to prevent frozen appliances when temperatures plummet is to add an energy source in the form of heat. This is where self-limiting heating cables come into play.

Using self-regulating heating cables ensures that your home or commercial building is protected against frozen roof gutters, burst water pipes, fire pipes, hot water pipes, and other residential and commercial pipe freeze.

Furthermore, thanks to their functionality and versatility of freeze protection appliance, you can be able to evade frost damage to service lines and buildings as the heating cables will protect all your pipes.

Figure – Frozen Pipes. Photo Credit: ProTherm Industries

There are thousands of people admitted to the hospital each year because of injuries from snow/ ice-related falls. Installing self-regulating heating cables can provide a safe place for you to walk on or park your car during the snow season.

Self-regulating heating cables ensure there’s no ice or snow build-up on your pathways, stairs, and driveway.

Figure – Pathway Heating Cables. Photo Credit: Warmup

Are you a farmer? These cables can also be used to ensure that your animals are well fed all year round. They can be installed on animal feeding tank to melt ice from animal feeding sinks and de-freeze water consumed by domesticated animals.

How? Simple: heating cables automatically activate when they detect any ice formation or snow and automatically deactivate once the snow or ice melts.

Your roof and gutters can also benefit from heating cables. Self-regulating heating cables for your roof and drains prevent any snow and ice from forming into lumps.

As you know, lumps can be very dangerous if they fall and hit you when you are walking underneath. Also, ice lumps and frost from snow can damage your roofs, gutters, and downpipes.

Therefore, it is necessary to install roof and gutter heat cables

NB: Ensure you connect the cable in areas above the edges of the roof (the eaves) to prevent any melting snow from freezing again when it starts to drain into the gutters.

How does the cable work on your roof and gutter? It automatically releases high heat levels whenever it’s covered by ice or snow and as the snow or ice melts, it decreases its output power.

You can lay the heating cables directly in your roof gutters or leave them hanging inside your downpipe.

* More on how to safely install self-regulating heating cables in your home later.

We all know that almost all liquids and solids flow freely when heated including syrup, molten glass, food-processing oils, honey, tar, water, sulfuric acid, and even motor oil.

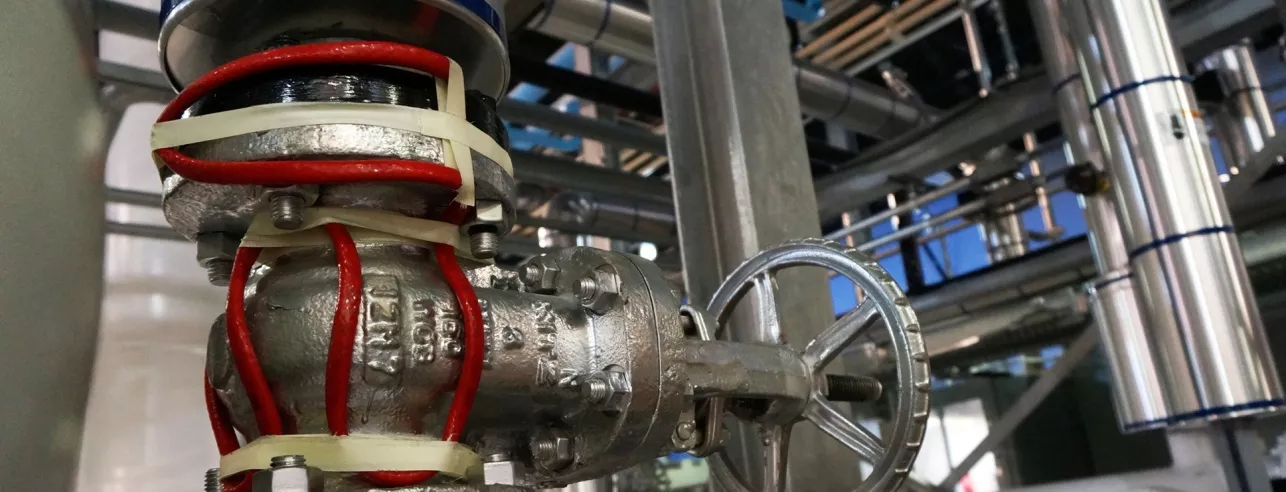

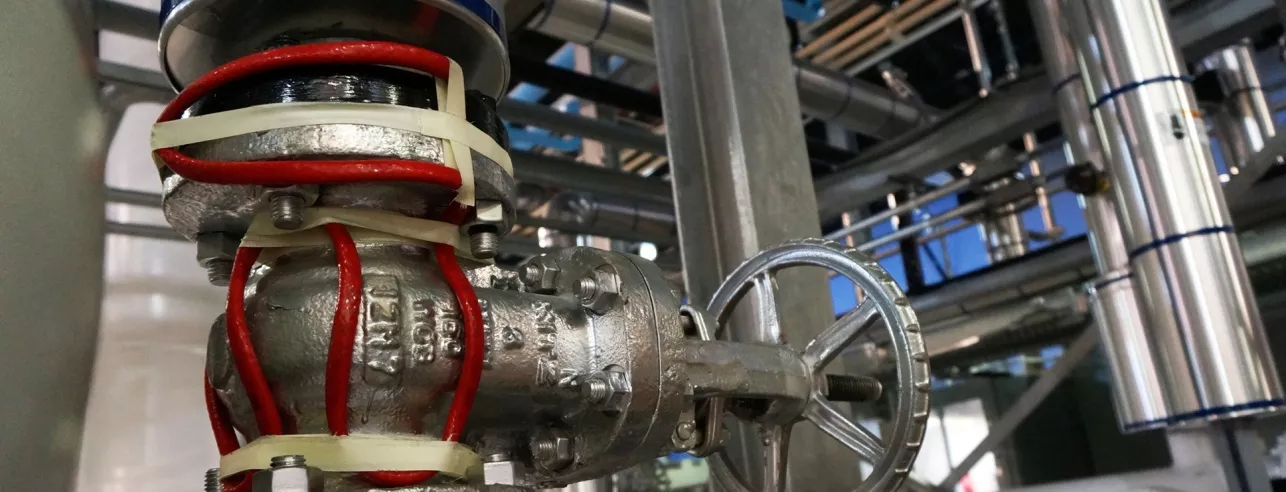

Figure – Self Regulating Heating Cable for Industry

Heating cables can be used for industrial purposed to heat chemicals and keep the liquids flowing constantly. The best part? The cables will not contaminate or burn any of the fluids. Additionally, heating cables are capable of reaching up to 500 degrees F.

As you already know, some materials will automatically become solid if they don’t have a constant and consistent heat source. With process temperature applications, there is usually a need for flow viscosity control for certain chemicals and fluids such as acids, fuel oils and lubes, certain plastics, thermal power plant desulfurization, CEMs (smoke sampling analysis), resins, and even fertilizers.

Self-limiting heating cables are able to avail a stable process temperature control and maintenance when applied.

Most of the mentioned fluids need a constant temperature ranging from 60 up to 120 degrees C and a maximum exposure temperature of 215 degrees C. You can use self-limiting technology to maintain high temperatures that will ensure the fluids and other components don’t cool and freeze or overheat.

NB: The heating cables you use needs to be able to withstand high operating temperatures over a long period.

Some structures are so big and heavy that you can’t just put them into an oven for curing. Various self-regulating heating cable manufacturers such as Jiahong China construct cables for composite curing and repairing.

You can use self-limiting heating cables in a variety of industries such as aerospace (airplanes, jets, etc.,), marine (ships, yachts, etc,), wind energy (such as wind power turbines), and many other types of composite fiber structures.

The cables use a hot bonding method that you can use to cure wet layups, infuse resin, prepreg, and bond metal. You will be surprised by the quality cure cycles, how precise and efficient heating cables are when used for composite curing.

Things to Consider Before Purchasing a self-Regulating Heating Cable

Before choosing a heating cable, you need to ensure that it’s approved for use in ordinary (nonclassified) and hazardous (classified) locations. For specific approval information, always refer to the product’s specification sheet provided.

Self-regulating heating cables for hazardous areas need to be certified in accordance with the requirements of the applicable standards for their type of protection for potential explosive gas and/or combustible dust atmosphere.

The heating manufacturer you choose to work with needs to be in compliance with safety requirements from:

- The standard for the Testing, Design, Installation, and Maintenance of Electrical Resistance Heat Tracing for Industrial Application

- The standard for the Testing, Design, Installation, and Maintenance of Electrical Resistance Heat Tracing for Commercial Application

- National electrical Code International Electrical Code Series

- And the Electrical Health and Safety Requirements bodies

The nominal output rating depends on the power output and the circuit length. For a simpler explanation, nominal power output for self-regulating heating cables is determined by measuring the electric or heat current (power output) and the length to know the voltage needed in a circuit.

* The higher the pipe temperature, the lower the wattage needed. Remember the pipe temperature varies depending on the surface temperatures.

We’ve designed a table using two different voltages needed for metal pipes to help you better understand;

| 208 V |

Power Output Range |

Circuit Length |

| 0.82 |

0.96 |

| 0.85 |

0.94 |

| 0.89 |

0.92 |

| 277 V |

Power Output Range |

Circuit Length |

| 1.13 |

1.08 |

| 1.12 |

1.09 |

| 1.08 |

1.11 |

Keep in mind that this is an example of nominal power output rating. The circuit length and voltage will vary when the factors mentioned above change.

All heating cables have minimum installation temperate of -40 degrees C (-40 degrees F.) However, the process temperature maintenance (the freeze protection application), the intermittent exposure temperatures, and constant temperatures depend on the type of heating cable you buy (low temperature, medium, high, or super high.)

To prevent creasing, the minimum bending radius of all heating cables should be 25 mm (1.0 inch)

For piping, your cable dimensions should be the total amount of heating cable required for the pipe length. For straight heating cable run, the dimensions are equal to the entire length of the piping. Add at least 1 meter to allow for the entry into the junction box and the end seals. Additionally, add a heating cable length of 5 – 10% for flanges, bends, elbows, etc.

For spiral piping, the installed cable dimensions = spiral factor X pipe length.

The circuit length is based on several conditions that must be taken into account including:

- Operating voltage

- The heating cable selected (watt density and type)

- Length of piping including extra allowance

- Expected start-up temperature

- Maximum allowable circuit length

- Available branch circuit breaker size

Our Jiahong China self-regulating heating cable systems are super safe and cost saving. They are certified for unconditional T-rating in accordance with European and American standards. You can rest assured knowing the surface temperature of the heating cable will never exceed its T-class temperature.

Thanks to its self-regulating principle, Jiahong China’s system saves energy and thus, operational costs. Finally, the system requires minimal maintenance and is entirely resistant to all pipe maintenance procedures. For more information, don’t hesitate to contact us.