- Home

-

Products

- Heating Cables/Heat-tracing Cables

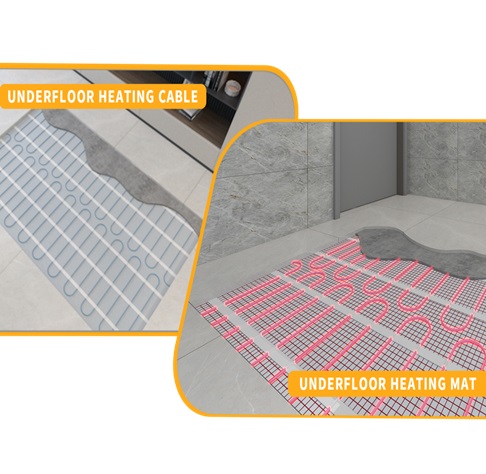

- Underfloor Heating Cable

- Self Regulating Heating Cable

- Constant Wattage Heating Cable

- Outdoor Snow Melt Cable

- Tubing Bundle

- Heat Tracing Accessories

- Application

- Projects

- About

- Support

- Contact Us